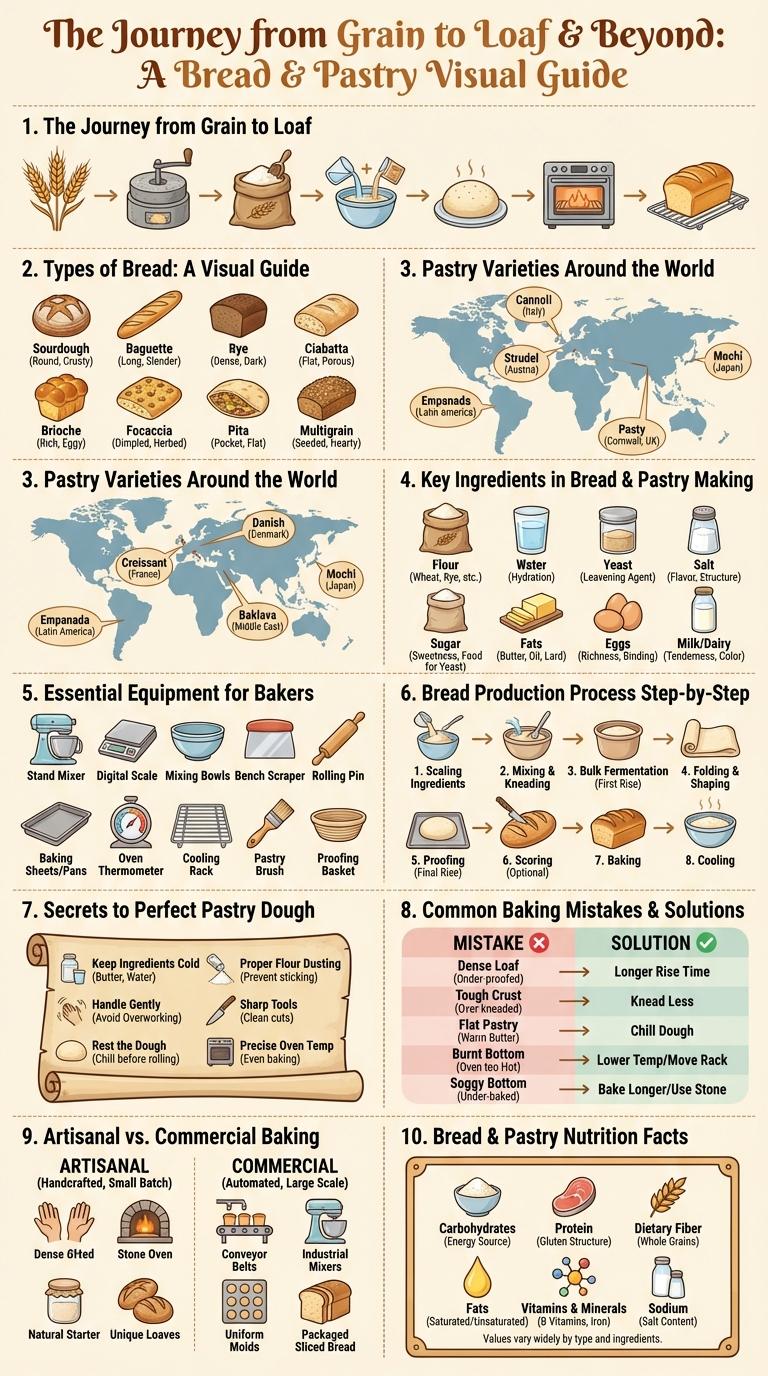

Bread and pastry production combines traditional baking techniques with modern technology to create a variety of delicious products. Understanding the step-by-step process from ingredient selection to baking enhances the appreciation of these staple foods. This infographic visually breaks down the key stages involved in crafting bread and pastries, highlighting crucial factors that impact quality and flavor.

The Journey from Grain to Loaf

Bread and pastry production transforms simple grains into delicious, baked goods enjoyed worldwide. This journey involves multiple precise steps to ensure quality and taste.

- Grain Harvesting - Wheat and other grains are carefully harvested from fields, ensuring optimal quality for baking.

- Milling - Grains are ground into flour, separating bran and germ to produce different flour types.

- Dough Preparation - Flour is mixed with water, yeast, and other ingredients to form dough, initiating fermentation for flavor development.

- Proofing and Shaping - Dough is allowed to rise, then shaped into loaves or pastry forms to prepare for baking.

- Baking - The shaped dough is baked at precise temperatures, transforming it into bread or pastry with desired texture and aroma.

The entire production process from grain to loaf emphasizes quality control and craftsmanship to produce consistently flavorful baked goods.

Types of Bread: A Visual Guide

Bread comes in various types, including white, whole wheat, sourdough, rye, and multigrain, each with unique flavors and textures. Pastry production involves creating flaky, buttery treats such as croissants, danishes, and tarts using techniques like laminating and proofing. Understanding the ingredients, fermentation, and baking methods is essential for producing quality bread and pastries.

Pastry Varieties Around the World

Bread and pastry production reflects rich cultural diversity across the globe. Unique recipes and techniques create distinct pastry varieties cherished worldwide.

- French Croissant - A flaky, buttery pastry made using laminated dough, symbolizing French baking tradition.

- Italian Cannoli - Tube-shaped shells filled with sweetened ricotta cheese, popular in Sicilian desserts.

- Middle Eastern Baklava - Layers of filo pastry filled with nuts, sweetened with honey or syrup for a rich flavor.

Key Ingredients in Bread & Pastry Making

What are the key ingredients in bread and pastry making? Flour and water form the base for both bread and pastries, providing structure and moisture. Yeast or chemical leavening agents create rise, while fats and sugars add flavor and texture.

Essential Equipment for Bakers

Bread and pastry production demands specialized equipment to ensure consistency, quality, and efficiency. Bakers rely on tools that enhance dough preparation, baking, and finishing processes.

- Dough Mixer - A powerful machine designed to knead and blend ingredients uniformly, essential for consistent dough texture.

- Proofer - A controlled environment chamber that promotes optimal yeast fermentation and dough rising.

- Oven - Industrial ovens with precise temperature control ensure even baking and perfect crust formation.

- Dough Divider - Equipment that accurately portions dough into equal pieces, improving production speed and product uniformity.

- Pastry Blender - Hand or machine tool used to mix fat into flour, crucial for flaky pastry textures.

Bread Production Process Step-by-Step

Bread production involves several key steps that transform raw ingredients into fresh, delicious bread. Understanding each stage helps ensure consistent quality and flavor.

The process starts with mixing flour, water, yeast, and salt to create dough. Next, the dough undergoes kneading to develop gluten, which provides structure. Afterward, the dough is left to ferment, allowing yeast to produce carbon dioxide and create air pockets.

Secrets to Perfect Pastry Dough

Mastering the secrets to perfect pastry dough involves using cold ingredients and handling the dough minimally to maintain flakiness. Incorporating the right fat-to-flour ratio ensures a tender, flaky texture essential for pastries. Resting the dough in the refrigerator allows gluten to relax, preventing shrinkage during baking and resulting in a crisp, delicate crust.

Common Baking Mistakes & Solutions

Baking bread and pastries requires precision, yet common mistakes can affect the final product's texture and flavor. Understanding these errors allows bakers to achieve consistent, high-quality results.

Overproofing dough leads to a dense texture, while underproofing results in poor rise and heaviness. Adjusting proofing times based on room temperature and dough type can prevent these issues.

Incorrect oven temperature causes uneven baking or burnt crusts. Using an oven thermometer ensures accurate heat levels and optimal baking conditions.

Using expired or inactive yeast hampers dough rise and flavor development. Always check yeast freshness and proof it before mixing with other ingredients.

Artisanal vs. Commercial Baking

Bread and pastry production varies significantly between artisanal and commercial baking methods. Artisanal baking involves small-scale, handcrafted processes emphasizing quality and tradition.

Commercial baking focuses on large-scale production with automated equipment to maximize volume and consistency. Ingredients and techniques often differ to enhance shelf life and cost efficiency.