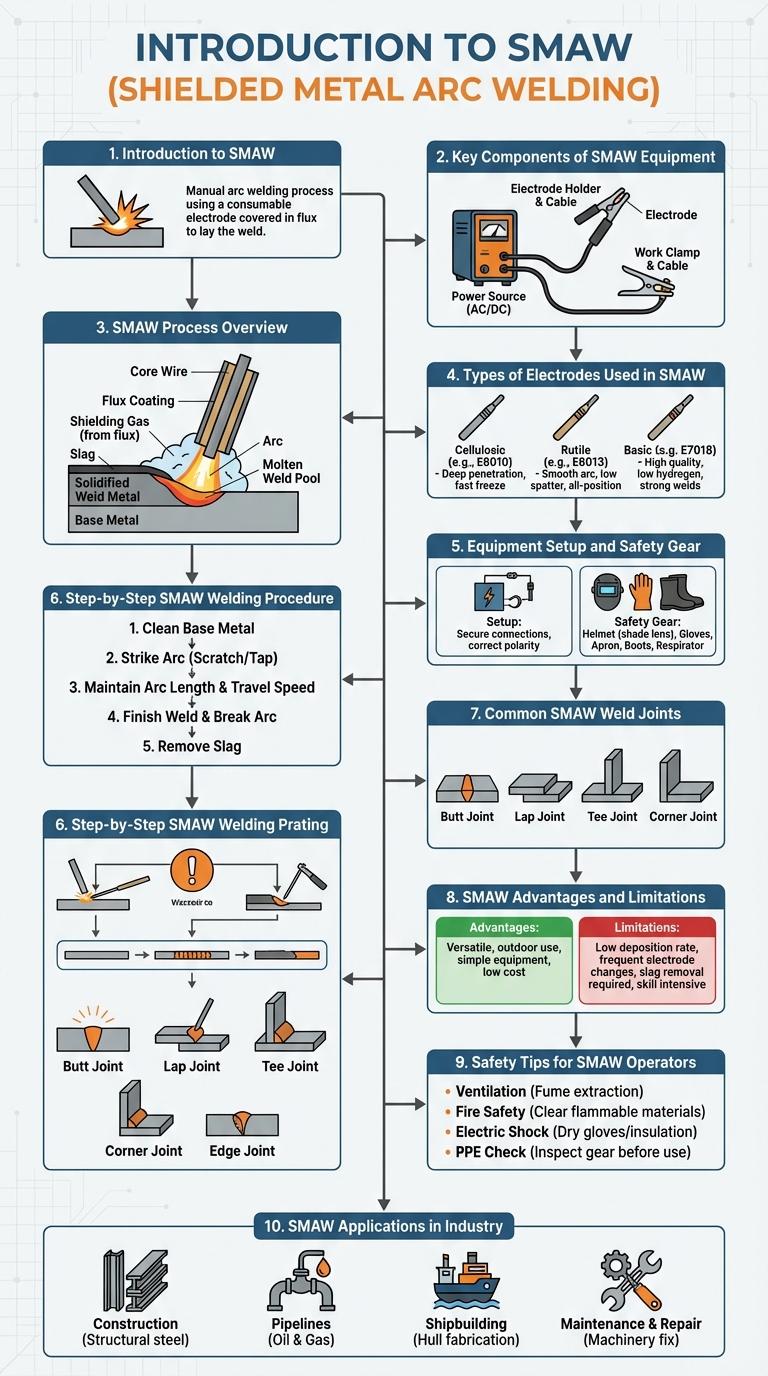

Shielded Metal Arc Welding (SMAW) is a versatile and widely used welding process known for its simplicity and effectiveness. The infographic breaks down key components, techniques, and safety measures, providing a comprehensive overview suitable for both beginners and professionals. Visual representations highlight electrode types, welding positions, and common troubleshooting tips for optimal results.

Introduction to SMAW (Shielded Metal Arc Welding)

Shielded Metal Arc Welding (SMAW) is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. It is widely used in construction, repair, and maintenance due to its simplicity and versatility. SMAW produces strong, high-quality welds on a variety of metals, making it essential for industrial applications.

Key Components of SMAW Equipment

Shielded Metal Arc Welding (SMAW) relies on essential equipment components to ensure effective welding. The key components include the welding machine, electrode holder, ground clamp, welding electrodes, and cables. Each part plays a critical role in creating a stable arc and high-quality welds.

SMAW Process Overview

Shielded Metal Arc Welding (SMAW) is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. This method is widely used for its simplicity and effectiveness on various metals and thicknesses.

- Electric Arc Creation - An electric arc is struck between the electrode and the workpiece to generate intense heat for melting metal.

- Flux-Coated Electrode - The electrode's flux coating melts during welding, forming a protective gas shield and slag to prevent contamination.

- Weld Pool Formation - Molten metal from both the electrode and base material forms a weld pool that solidifies into a strong joint.

Types of Electrodes Used in SMAW

Shielded Metal Arc Welding (SMAW) utilizes various types of electrodes designed for different applications and materials. The choice of electrode significantly impacts weld quality and mechanical properties.

Common electrode types include rutile, basic, cellulose, and iron powder electrodes. Each type varies by coating composition, arc stability, penetration depth, and suitability for welding conditions.

Equipment Setup and Safety Gear

Shielded Metal Arc Welding (SMAW) requires essential equipment for effective operation, including a welding power source, electrode holder, ground clamp, and welding electrodes. Proper setup ensures consistent arc stability and high-quality welds.

Safety gear is crucial when performing SMAW to protect against sparks, UV radiation, and electric shock. Key safety items include a welding helmet with auto-darkening filter, flame-resistant gloves, protective clothing, and safety boots.

Step-by-Step SMAW Welding Procedure

Shielded Metal Arc Welding (SMAW) is a manual arc welding process using a consumable electrode coated in flux. This method is popular for its versatility and portability in various welding applications.

Follow these steps for a successful SMAW welding procedure:

- Preparation - Clean the metal surface and select the appropriate electrode for the material and welding position.

- Set Up - Adjust the welding machine to the recommended current settings based on electrode type and thickness.

- Striking the Arc - Strike the electrode against the workpiece to create a stable arc, initiating the weld pool.

- Welding Technique - Maintain a consistent travel speed and electrode angle to ensure proper fusion and bead formation.

- Post-Weld - Allow the weld to cool, then remove slag using a chipping hammer and wire brush for inspection.

Common SMAW Weld Joints

What are the common SMAW weld joints used in metal fabrication? Shielded Metal Arc Welding (SMAW) typically employs butt, lap, corner, edge, and T-joints for various structural applications. Each joint type provides specific mechanical strength and is chosen based on the welding project's design requirements.

SMAW Advantages and Limitations

Shielded Metal Arc Welding (SMAW) is a versatile and widely used welding process known for its simplicity and cost-effectiveness. It employs a consumable electrode coated with flux to create strong, durable welds in various metals.

SMAW offers advantages such as portability, allowing welders to work in remote or confined spaces without the need for external shielding gas. Its equipment is relatively inexpensive and easy to maintain, making it suitable for fieldwork and repair tasks. However, SMAW produces slag that must be removed after welding, which can slow down the process and require additional cleanup.

Safety Tips for SMAW Operators

Shielded Metal Arc Welding (SMAW) requires strict adherence to safety protocols to prevent accidents and injuries. Proper protective gear and workspace management are essential for SMAW operators.

- Wear Appropriate PPE - Use welding helmets, gloves, flame-resistant clothing, and safety boots to protect against burns and electric shock.

- Ensure Proper Ventilation - Maintain adequate airflow to avoid inhaling harmful welding fumes and gases during the welding process.

- Check Equipment Regularly - Inspect cables, electrode holders, and welding machines before use to ensure safe and efficient operation.

- Keep Flammable Materials Away - Remove any combustible items from the welding area to prevent fire hazards.

- Use Grounding Techniques - Proper grounding of the equipment reduces the risk of electric shock and improves operator safety.

Adhering to these safety tips reduces the risk of injury and promotes a safer working environment for SMAW operators.