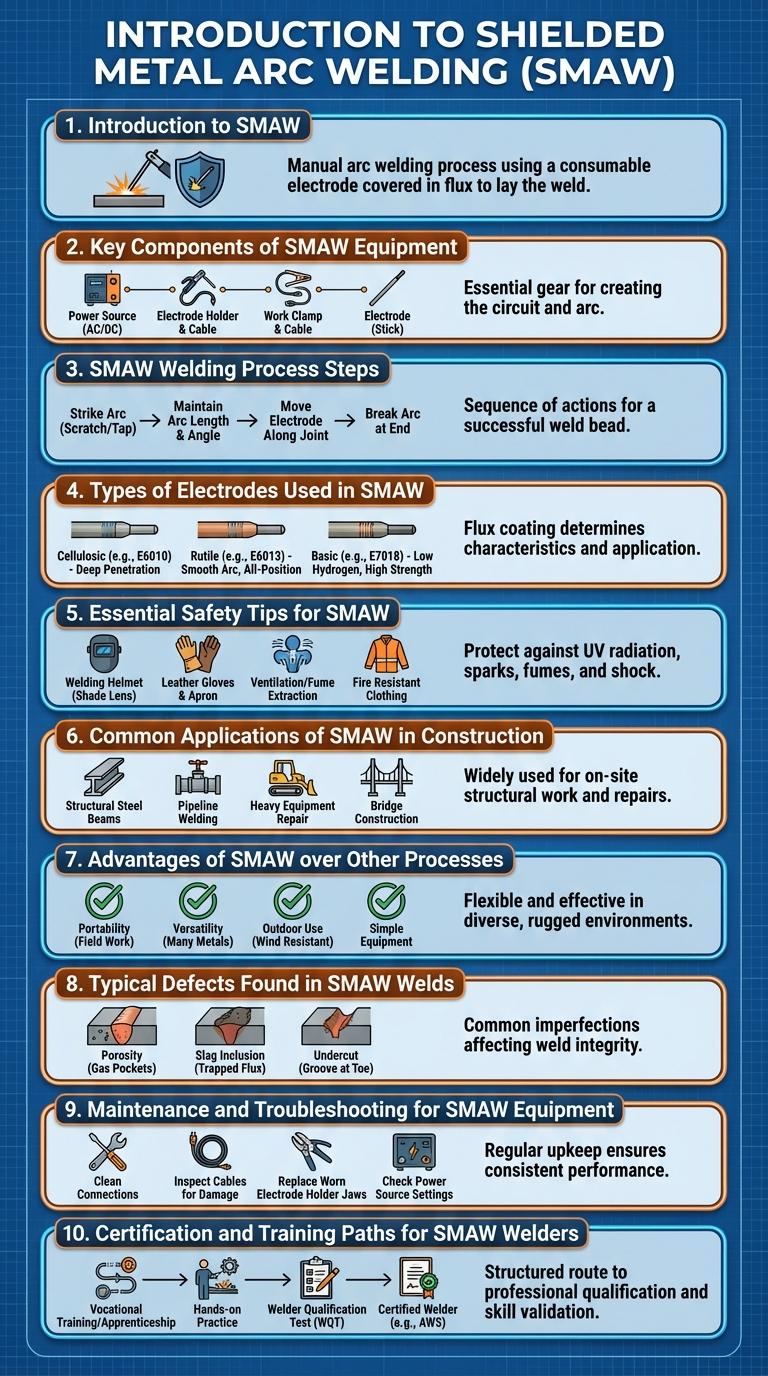

Shielded Metal Arc Welding (SMAW) is a versatile process widely used in construction for joining metals with precision and strength. This infographic highlights key elements of SMAW, including equipment setup, electrode selection, and safety measures. Understanding these aspects enhances welding efficiency and ensures durable structural integrity.

Introduction to Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding (SMAW) is a versatile welding process that uses a consumable electrode coated in flux to join metals. It is commonly known as stick welding and is widely used in construction, maintenance, and repair work.

The flux coating generates a shielding gas and slag to protect the molten weld pool from atmospheric contamination. This method allows welding of various metals, including steel, stainless steel, and cast iron, making it suitable for diverse applications.

Key Components of SMAW Equipment

Shielded Metal Arc Welding (SMAW) is a versatile welding process widely used in construction and repair. Understanding the key components of SMAW equipment is essential for effective and safe welding operations.

- Electrode Holder - Holds the welding electrode securely and conducts current to create the arc.

- Ground Clamp - Ensures a stable electrical connection to the workpiece, completing the circuit.

- Welding Power Source - Provides the necessary electric current, either AC or DC, to generate and maintain the arc.

- Welding Electrode - A consumable rod coated with flux that melts to form the weld and shield the molten metal from contamination.

- Cable and Connectors - Transmit electrical current between the power source, electrode holder, and ground clamp with flexibility and durability.

SMAW Welding Process Steps

SMAW (Shielded Metal Arc Welding) is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. The welding steps include striking an arc between the electrode and the base metal, melting the electrode to form the weld pool, and allowing the flux coating to create a shielding gas and slag to protect the weld from contamination. The process requires careful control of electrode angle, arc length, and travel speed to produce strong, defect-free welds.

Types of Electrodes Used in SMAW

The Shielded Metal Arc Welding (SMAW) process uses various electrode types tailored for specific materials and applications. Understanding electrode characteristics enhances weld quality and efficiency.

- Cellulosic Electrodes - These electrodes produce a forceful arc and deep penetration, ideal for pipeline welding.

- Rutile Electrodes - Known for smooth slag removal and easy arc striking, suitable for thin metals and general fabrication.

- Iron Powder Electrodes - Contain iron powder to increase deposition rates and improve weld bead appearance.

Essential Safety Tips for SMAW

Shielded Metal Arc Welding (SMAW) is a versatile and widely used welding process essential in construction and metal fabrication. Ensuring safety during SMAW protects welders from electrical hazards, burns, and harmful fumes.

Wear appropriate personal protective equipment (PPE) including a welding helmet with proper shade, flame-resistant gloves, and protective clothing. Maintain good ventilation to prevent inhalation of toxic fumes generated during welding.

Common Applications of SMAW in Construction

Shielded Metal Arc Welding (SMAW) is widely used in construction for its versatility and strong weld quality. Common applications include welding structural steel frameworks, pipelines, and heavy equipment components. Its adaptability in outdoor and various environmental conditions makes SMAW a preferred choice for construction projects.

Advantages of SMAW over Other Welding Processes

Shielded Metal Arc Welding (SMAW) remains a preferred choice for many industrial applications due to its versatility and cost-effectiveness. Its simplicity makes it accessible for both fieldwork and shop environments.

- Portability - SMAW equipment is lightweight and compact, enabling easy transportation and use in remote or confined locations.

- Cost Efficiency - The process requires minimal consumables and equipment investment, reducing overall project expenses.

- Versatility - SMAW works effectively on various metals and thicknesses, making it suitable for diverse welding tasks.

SMAW's simplicity and adaptability make it an advantageous choice over more complex welding techniques.

Typical Defects Found in SMAW Welds

| Typical Defects | Description |

|---|---|

| Porosity | Gas pockets trapped inside the weld metal causing weak spots and reduced strength. |

| Cracks | Fractures in the weld caused by excessive stress or improper cooling rates. |

| Slag Inclusions | Non-metallic solid material trapped inside the weld, leading to poor fusion and structural weakness. |

| Undercut | A groove melted into the base metal adjacent to the weld toe, reducing cross-sectional thickness and strength. |

| Lack of Fusion | Incomplete joining of the weld metal to the base metal or previous weld pass, causing low joint integrity. |

Maintenance and Troubleshooting for SMAW Equipment

What are common maintenance practices for SMAW equipment? Regular inspection of cables, electrode holders, and ground clamps is essential to ensure safe operation. Cleaning and tightening connections prevent equipment failure during welding tasks.

How often should SMAW machines be checked for potential issues? Routine checks should be performed before each use and detailed maintenance monthly. This schedule helps identify wear and tear early, preventing downtime.

What troubleshooting steps help resolve electrode sticking in SMAW? Inspect the welding machine settings and adjust amperage according to the electrode type. Clean or replace electrodes and check for proper workpiece grounding to improve arc stability.

How to address inconsistent arc performance in shielded metal arc welding? Verify all electrical connections are secure and free from corrosion or damage. Replace worn cables or terminals to maintain consistent electrical flow for stable arc performance.

What safety tips should be followed during SMAW equipment maintenance? Always disconnect power before servicing to avoid electric shock. Use protective gloves and eye protection when handling electrodes and cleaning machine parts.