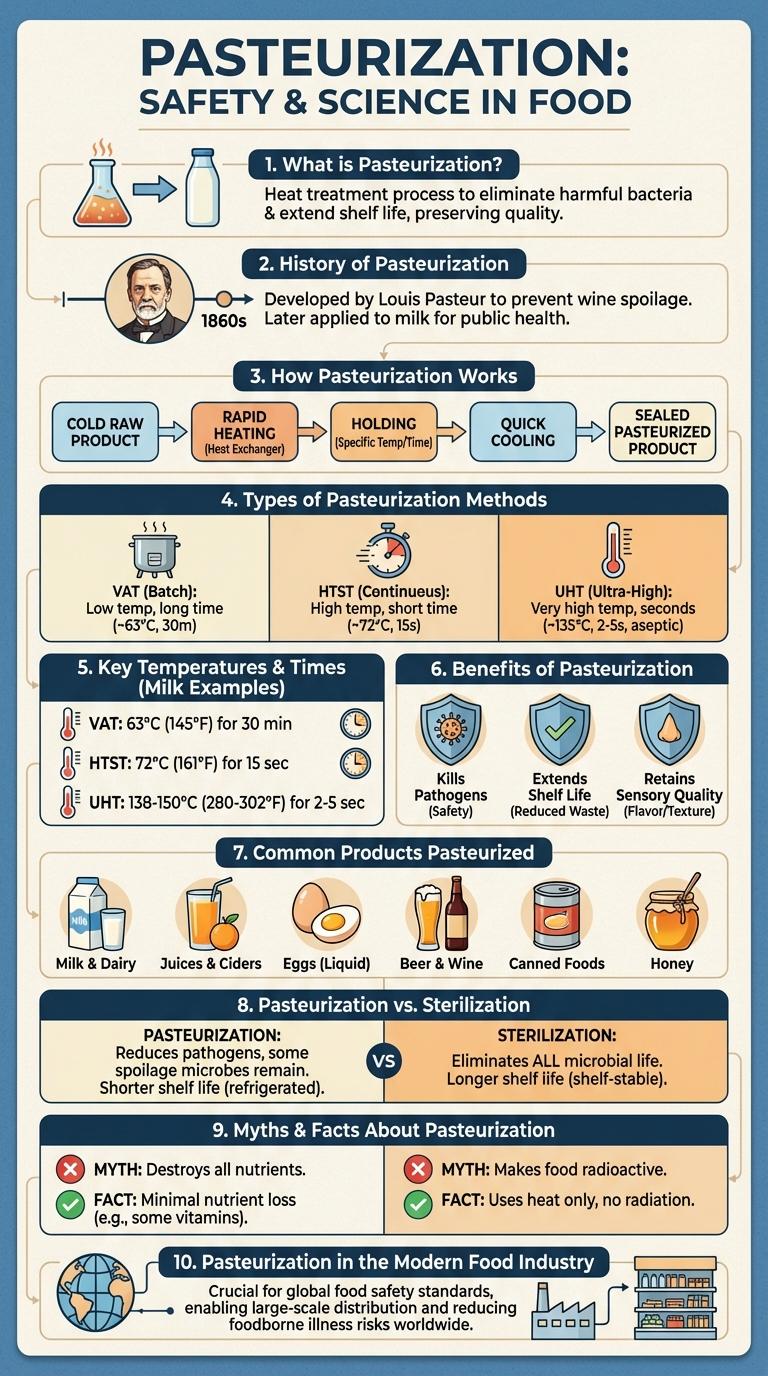

Pasteurization is a crucial food safety process that uses controlled heat to eliminate harmful bacteria and extend shelf life in beverages and perishable foods. This infographic visually breaks down the key steps, benefits, and types of pasteurization methods employed across the food industry. Understanding these elements helps consumers and producers ensure safer consumption and reduce foodborne illnesses.

What is Pasteurization?

Pasteurization is a heat treatment process that kills harmful bacteria in food and beverages. It helps extend shelf life while preserving taste and nutritional value.

Developed by Louis Pasteur in the 19th century, this method is widely used for milk, juice, and other perishable products. The process involves heating liquids to a specific temperature for a set time, then rapidly cooling them.

History of Pasteurization

Pasteurization is a heat treatment process developed by French scientist Louis Pasteur in the 1860s to kill harmful microorganisms in beverages. Initially used to prevent wine spoilage, the method was later adapted for milk and other perishable liquids. This pioneering technique revolutionized food safety and preservation worldwide.

How Pasteurization Works

| Step | Description |

|---|---|

| Heating | Liquid food is heated to a specific temperature between 60degC and 85degC (140degF to 185degF) to destroy harmful microorganisms. |

| Holding | The heated liquid is maintained at this temperature for a set time, usually between 15 seconds and 30 minutes, depending on the method. |

| Cooling | The liquid is rapidly cooled to prevent growth of any remaining bacteria and preserve taste and quality. |

| Main Purpose | To increase the safety and shelf life of food products by reducing microbial load without compromising nutritional value. |

| Common Applications | Milk, fruit juices, dairy products, and certain alcoholic beverages. |

Types of Pasteurization Methods

Pasteurization is a heat treatment process used to kill harmful microorganisms in food and beverages. This method enhances food safety and extends shelf life without significantly affecting nutritional value.

There are several types of pasteurization methods commonly used in the food industry. High-Temperature Short-Time (HTST) pasteurization heats products to around 72degC for 15 seconds, ideal for milk and dairy products. Ultra-High Temperature (UHT) pasteurization reaches temperatures of 135degC or higher for 2 to 5 seconds, allowing products to be shelf-stable without refrigeration. Low-Temperature Long-Time (LTLT) pasteurization involves heating at 63degC for 30 minutes, often used in smaller scale dairy processing. Another method, batch pasteurization, heats food in large containers and is less common but still effective for certain products.

Key Temperatures & Times

What are the key temperatures and times required for pasteurization? Pasteurization involves heating food or liquids to specific temperatures for set durations to eliminate harmful microorganisms. The process ensures safety while preserving flavor and nutritional value.

| Pasteurization Method | Temperature & Time |

|---|---|

| Low-Temperature Long-Time (LTLT) | 63degC (145degF) for 30 minutes |

| High-Temperature Short-Time (HTST) | 72degC (161degF) for 15 seconds |

| Ultra-High Temperature (UHT) | 135degC (275degF) for 2-5 seconds |

| Batch Pasteurization | 62-65degC (143.6-149degF) for 30 minutes |

Benefits of Pasteurization

Pasteurization is a heat treatment process that eliminates harmful bacteria in food and beverages, ensuring safety for consumption. It significantly extends the shelf life of products like milk, juice, and dairy without compromising nutritional value.

This process reduces the risk of foodborne illnesses such as salmonella and listeria. Pasteurization also helps preserve flavor and texture, making products more appealing and reliable for consumers.

Common Products Pasteurized

Pasteurization is a heat treatment process that kills harmful bacteria in food and beverages. It extends shelf life and ensures safety without significantly affecting taste or nutrition.

- Milk - Milk undergoes pasteurization to eliminate pathogens like Salmonella and Listeria, making it safe for consumption.

- Juices - Fruit juices are pasteurized to destroy harmful microbes while preserving flavor and vitamins.

- Egg Products - Liquid egg products are pasteurized to reduce the risk of Salmonella contamination while maintaining quality.

- Dairy Products - Cheeses and yogurts are often pasteurized to ensure microbial safety and prolong shelf life.

- Alcoholic Beverages - Some beers and wines are pasteurized to stabilize flavor and prevent spoilage by unwanted microorganisms.

Pasteurization vs. Sterilization

Pasteurization and sterilization are heat treatment processes used to increase food safety and shelf life. Both techniques target microorganisms but differ significantly in temperature and effects on food quality.

Understanding these differences is essential for choosing the appropriate method for food preservation.

- Temperature Range - Pasteurization uses mild heat typically below 100degC, whereas sterilization requires higher temperatures above 121degC.

- Microbial Impact - Pasteurization kills pathogenic bacteria but not all spores, while sterilization destroys all microorganisms and spores.

- Effect on Food Quality - Pasteurization better preserves flavor and nutrients; sterilization can alter taste and texture due to harsher heat.

Myths & Facts About Pasteurization

Pasteurization is a heat treatment process that kills harmful bacteria in food and beverages without compromising their nutritional value. Many believe pasteurization removes all nutrients, but it actually preserves most vitamins while ensuring safety. This method significantly reduces the risk of foodborne illnesses while maintaining taste and quality.